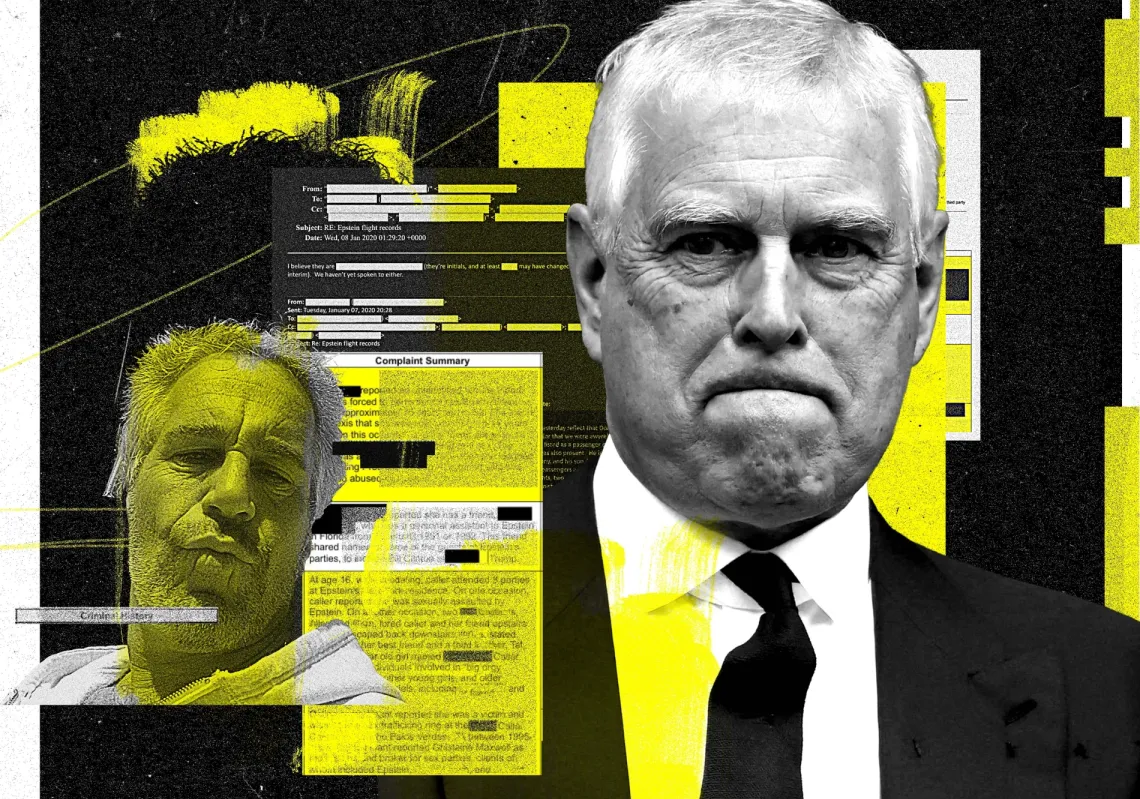

Saudi boys visit the Rolls-Royce stand at the 2013 International Luxury Motor Show in the capital Riyadh on October 29, 2013. (Fayez Nureldine/AFP/Getty Images)[/caption]

Saudi boys visit the Rolls-Royce stand at the 2013 International Luxury Motor Show in the capital Riyadh on October 29, 2013. (Fayez Nureldine/AFP/Getty Images)[/caption]

by Thomas W. Lippman

It was easy to be skeptical when Saudi Arabia’s economic planners decided nearly a decade ago to promote the development of a domestic automobile and truck manufacturing industry. It’s harder to be skeptical now. More and more, reports from business analysts and the trade press suggest that it might actually happen. One after another, international companies have announced tentative agreements or signed letters of intent to set up shop in the Kingdom.

The demand for motor vehicles is obvious: Long distances, good roads and a growing and relatively affluent population make the Kingdom an enticing market. Not so obvious is why those motor vehicles should be manufactured or assembled in Saudi Arabia instead of imported, as they have been since the first two Ford Model T’s arrived in Riyadh in 1924.

The answer lies in the government’s commitment to develop a self-sustaining industrial economy separate from the oil industry. Instead of simply exporting raw material and then importing finished goods, Saudi Arabia would do the processing and manufacturing itself, keeping the “added value” at home. Economic diversification has been the stated goal since at least the 1970s, but recent developments, such as the construction of a mammoth aluminum complex and growth in the output of plastics, signal that the goal is no longer just idle talk.

About 10 years ago, the government created the National Industrial Development Program to encourage the growth of five targeted industries that could grow in “clusters” of related businesses. For obvious reasons, industries that rely on ample supplies of lumber or water were excluded. Instead, the government selected automotive assembly, construction materials, metals processing, packaging, and consumer goods.

These were not to be started from scratch; they already existed to some degree. The idea of the “cluster industries” program was that the government—through land allocation, road construction and discounts on raw materials—could encourage them to grow in “clusters” of related operations, in the same way the computer chip industry attracted software developers and other related operations to Silicon Valley in California. Vehicle assembly, for example, would attract suppliers of auto glass, interior plastics, tires, seats and engine parts. At a presentation in Detroit in 2013, Development Program leaders projected an eventual output of 400,000 vehicles a year. That seems ambitious, but it is no longer laughable.

At the time the cluster plan was announced, Saudi Arabia already had a Daimler-Benz truck assembly plant, and General Motors was operating a bus factory for a Saudi company. Isuzu Motors of Japan has a plant in Dammam’s industrial zone that is making trucks from imported parts and is developing its own part-making center. The current target is an output of 25,000 vehicles a year by the end of 2017. In the most ambitious project, Jaguar Land Rover (JLR) Company, part of Indian car manufacturer TATA Motors, has signed a letter of intent with the National Industrial Cluster Development Program to establish a manufacturing facility in Yanbu. The factory has the potential to produce 50,000 Land Rovers a year by 2017. Daewoo of South Korea is also reportedly planning an assembly plant. Engineering students at King Saud University have even designed a modestly priced car to be built from scratch locally, the Ghazal, which a consortium including a Korean company is planning to put into production. Outside Jeddah, Toyota is operating a training school for service technicians.

If all the plans from these announcements and reports become reality, the auto and truck plants and related suppliers will employ thousands of workers. The Land Rover plant alone would have a work force of 5,000 people. The question is how many of those would be Saudis.

Industrial development and private-sector growth have benefited from Saudi Arabia’s membership in the World Trade Organization, which opened its markets and removed some tariff barriers. Competition has developed in industries that formerly were government monopolies, such as airlines and mobile telephone networks. To open jobs for Saudis, the government has deported thousands of foreign workers who were in the country illegally or had overstayed their visas. But Saudi Arabia is still struggling to overcome a painful history of failure in its efforts over previous decades to develop jobs for its citizens outside the oil industry and the government. Business groups and potential employers routinely complain that young Saudi men are poorly educated, lack the technical skills required by modern industry, and demand salaries well beyond their actual productive value. Women are widely said to make better employees, but many employers are reluctant to hire them because of transportation issues and the requirement to keep men and women separate in the workplace.

Corporations are in business to make money, and one way to do that is to hire as few people as possible, paying them the lowest wages the market will bear. In Saudi Arabia, that has meant hiring workers from South Asia who are well-trained, work long hours for low pay, and are very unlikely to strike or unionize.

As more young people—and more women—enter the work force, government planners know that they will face increasing pressure to provide them with job opportunities. If they can persuade young Saudis to work in factories and teach them how to do it, a growing auto industry would help.